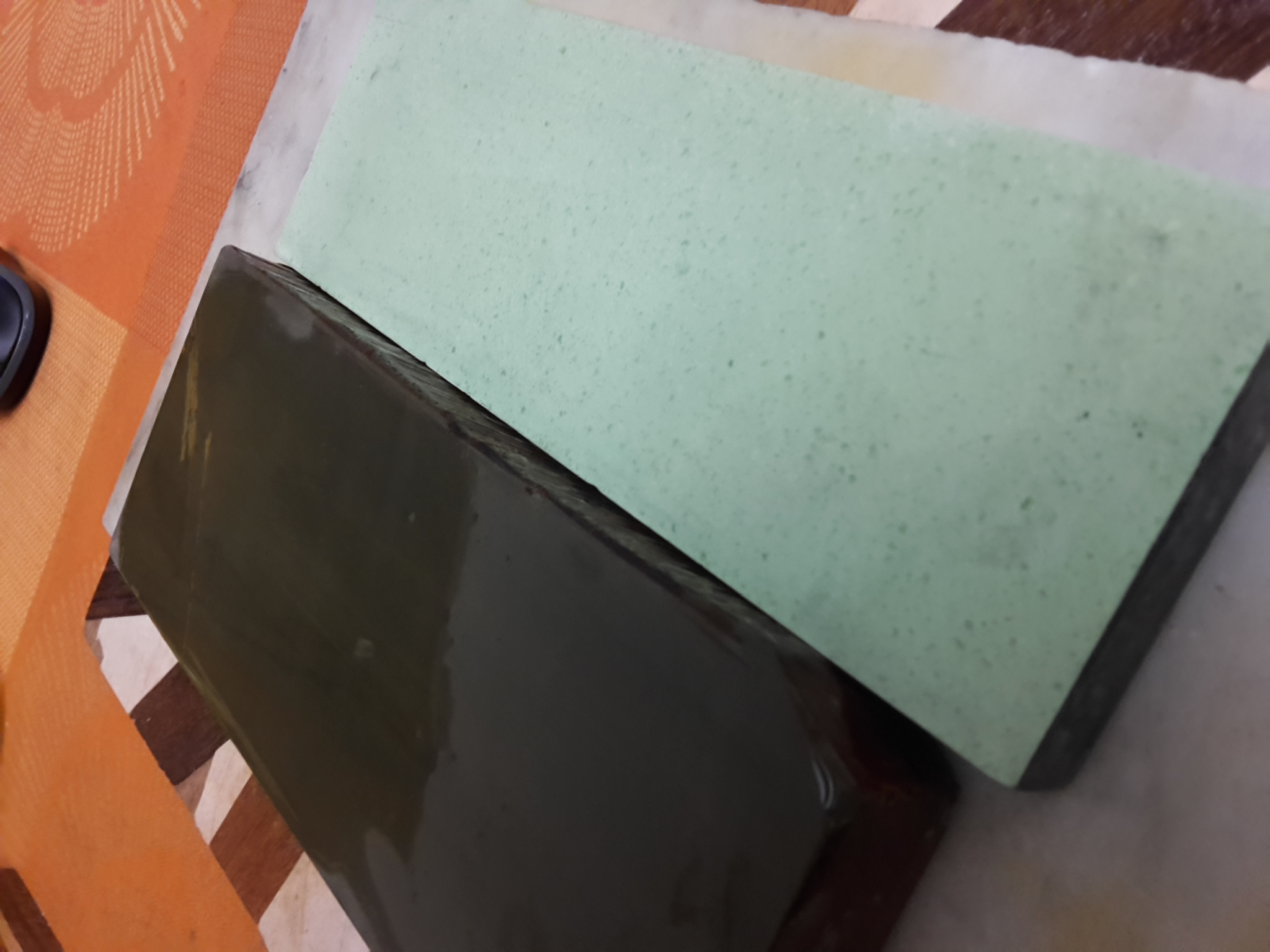

This design project is about compensating a problem in France: there is no natural fine sharpening stone quarry ! In Belgium is the fabulous coticule. In France the finest sharpening stone is the blue granit of the Vosges, which, at 2000 grit, is not fine enough.

This subject may seem anecdotical at best, but this not the case. Natural sharpening stone are simply the best, and extremely durable.

Furthermore, very fine sharpening stone are essential in a subtler way. Even if their use is marginal at best, they participate to the excellency of metal working culture in a country. This in turns impact the whole woodworking tools culture.

For instance, Germany has Thuringian water stone, Japan has several natural stone (Ozuku, Oouchi, …), etc.

So the idea is that even if there is no suitable natural stone in France, there is suitable natural material to build one. More precisely, there is a very famous fine sand that has been used for a long time in the quarry of Fontainebleau. Sand is very hard, and a suitable candidate to sharpening.

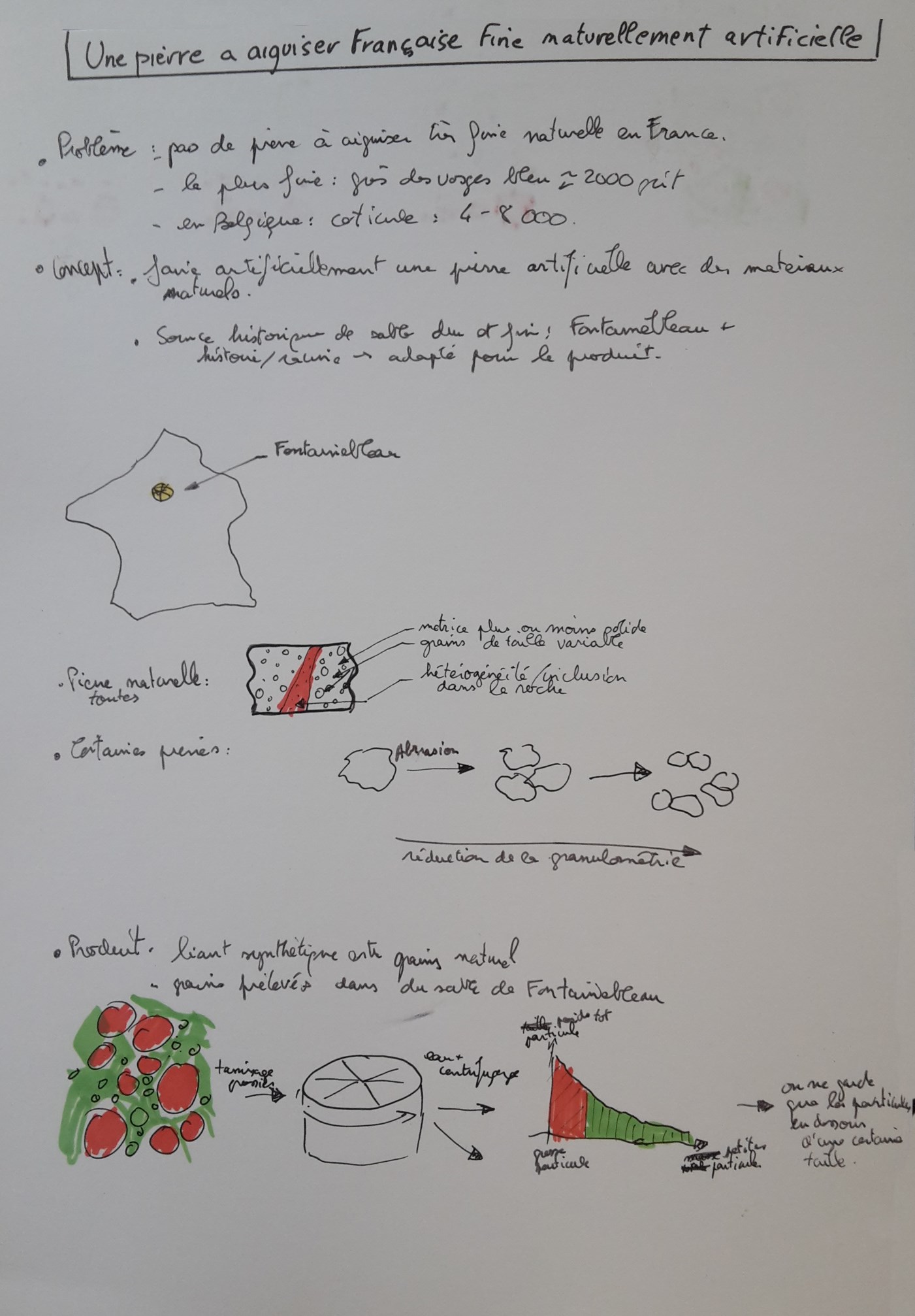

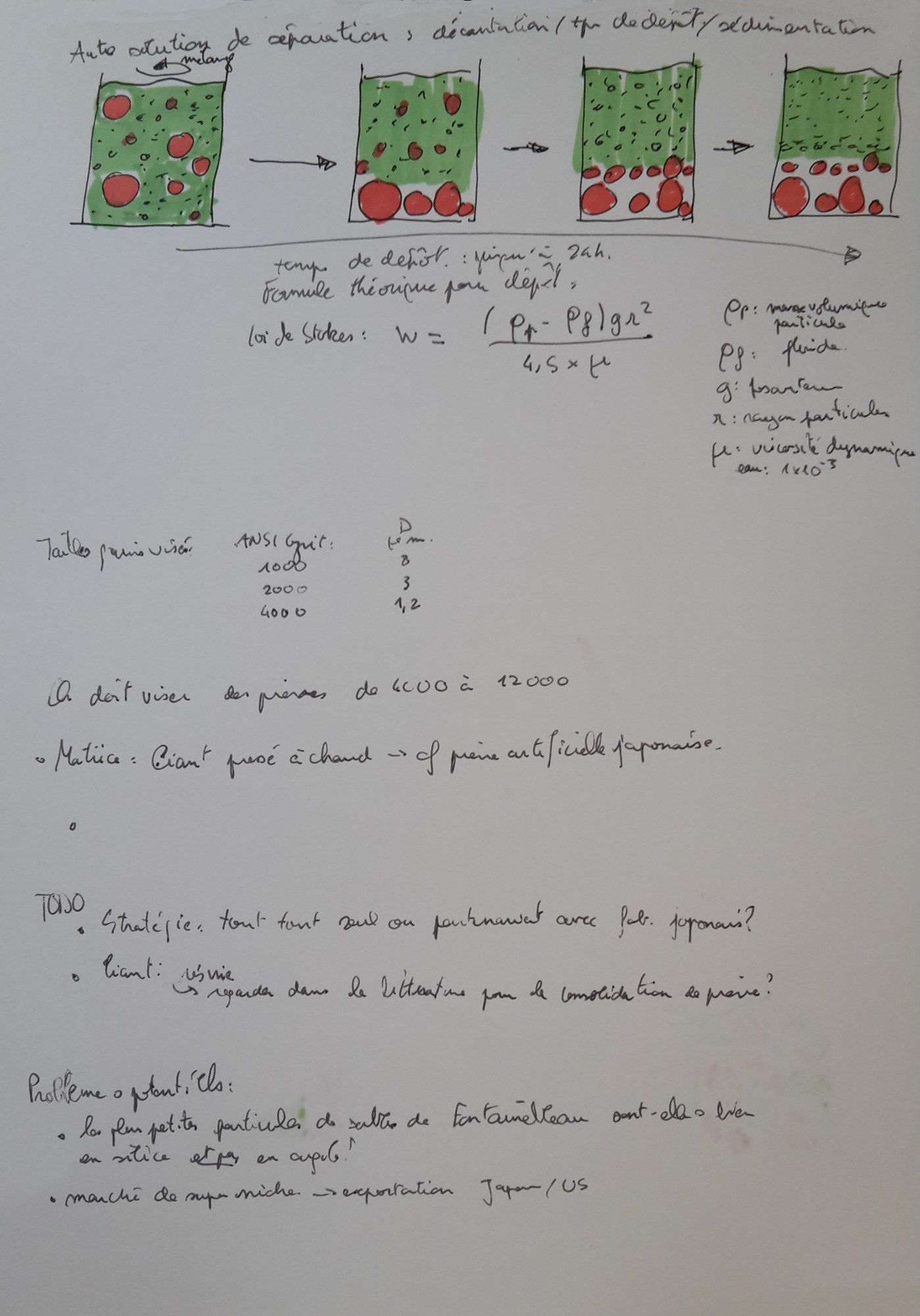

The last issue is then how to control the granulometry of the sand, and how to bind the grains into a stone. Both these problems have common industrial solution.