This project is more an open idea to explore, for which I tried to provide few proof of concept with the limited means I had available.

This project is more an open idea to explore, for which I tried to provide few proof of concept with the limited means I had available.

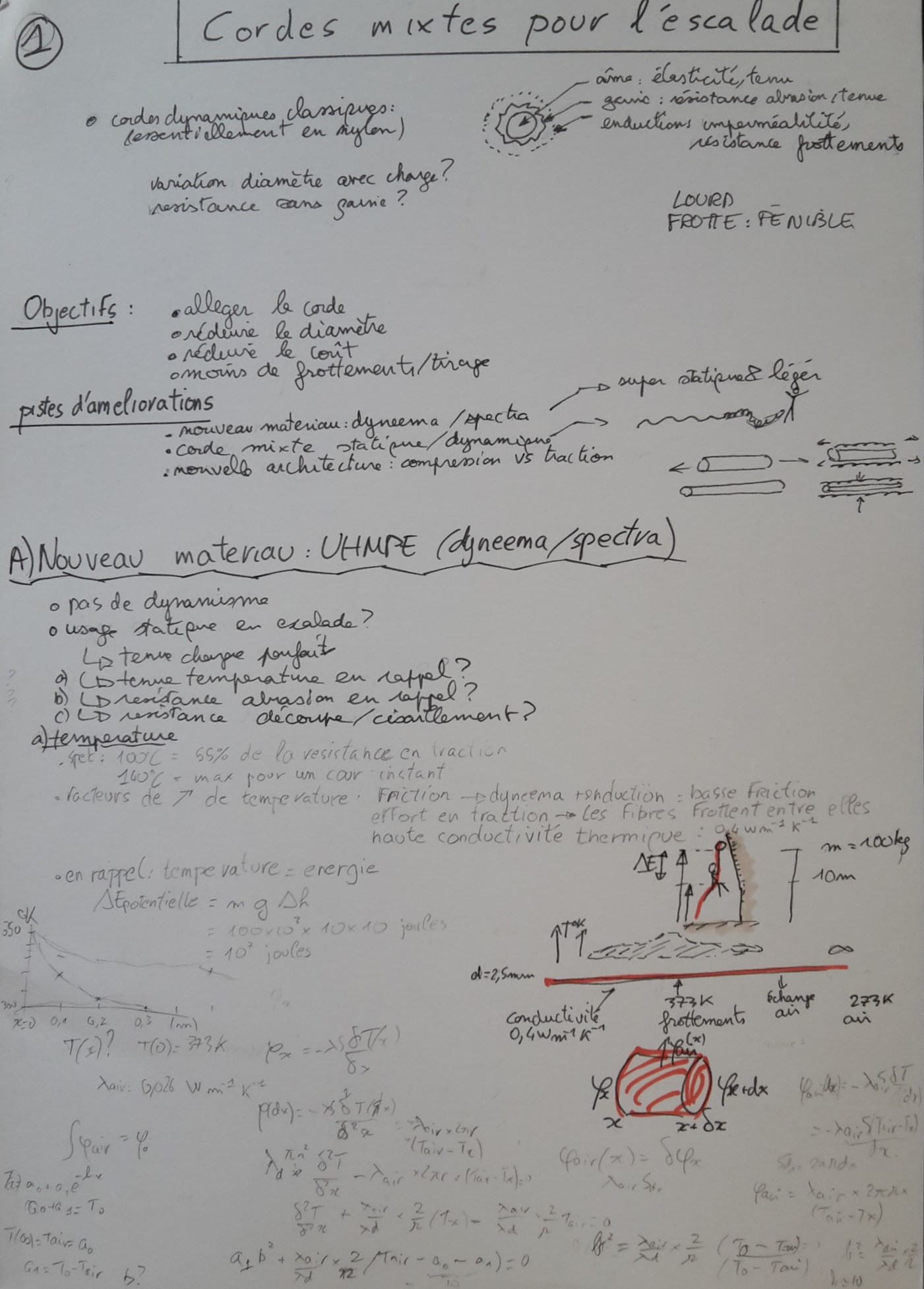

Context

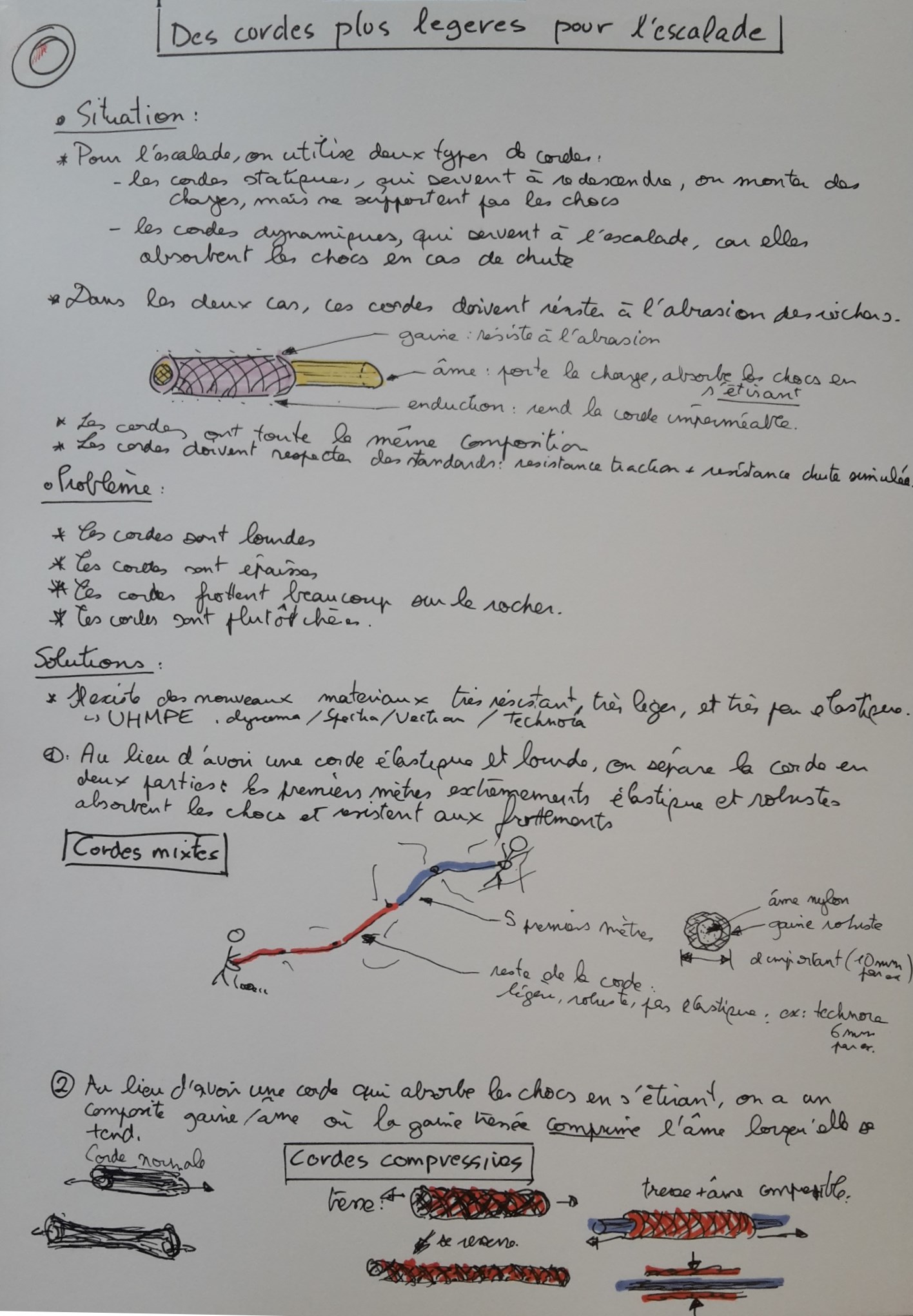

Climbing and Mountaineering is becoming quite popular, as it is a cool way to connect with nature, with a good physical challenge.

Issue is that things can degrade very quickly on the mountain (weather, equipment failure, exposure …). The recent philosophy has been to go as light as possible, as it allows increased agility.

When preparing bag for a 1 week expedition for instance, rope weight is the b°1 issue, by far (80 meters of rope > 3kg).

Besides, because rope is so heavy (and expensive), regular trekker can’t take it, even if it is a pretty neat element of security.

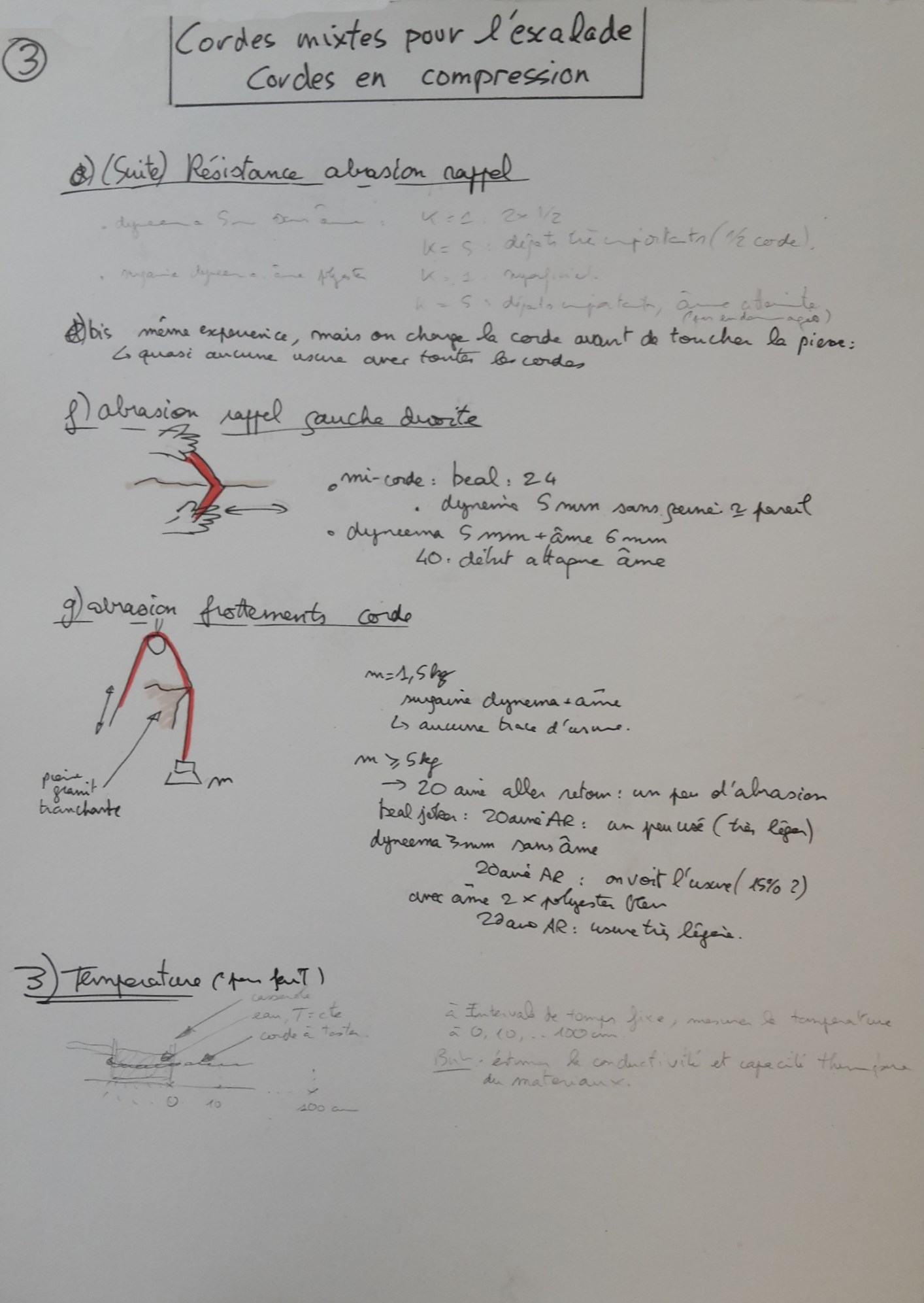

The Joker Beal, a typical light, high performance rope (9.1mm of diameter), is at 50g/m, and about 3€/m. It is heavy because it has to be able to absorb shock of a falling climber. In this scenario, the rope stretches to absorb energy. The energy is absorbed because the rope resist stretching.

Yet I discovered very high-performance rope in the world of competitive sailing. Such ropes are made of modern high-performance materials, are super light, super strong, but do not stretch at all. To give an example, a 4 mm SK99 dyneema braid can carry 2 tons (same as joker), yet weight only 6g/m (about 8 times less that the joker)

Problem

- Climbing rope are too heavy!

- Climbing rope have high drag

- Climbing rope are too expansive

Proposed solution

I tried to explore two solutions.

Mix rope

The first solution is an analysis of what a climbing rope does. A climbing rope

- can carry a very high mass

- can absorb shocks of a climber falling twice the height of the available rope without killing him.

- must resist abrasion from rocks to a certain extend

So you have essentially two contradictory goals: to carry a big mass the rope has to be rigid, to absorb shocks the rope has to stretch.

What I imagined is a mix-rope: The first 5 meters of the rope are highly resistant to abrasion, and are super stretchy. The rope is simply a modern climbing rope with more stretch.

The rest of the rope (75m or 95 m, typically), is composed of lightweight high-performance braid (dyneema/spectran/technora/etc.).

That way the total mass of say 100 meters of rope could go from 5kg to 0.25 + 1 kg!

The pros of this mixed-rope is that we can retain the best of both worlds:

- the climber can use traditional knots on the first part of the rope, and can sustain heavy falls (10 meters) without damage.

- the total rope weight is much less

- the rope drag is extremely decreased (less contact surface, less weight, high performance ropes are more slippery)

The cons are

- the two ropes parts won’t have the same diameter

- the second light part will have small diameter, thus needing specific belay equipment/skills

- the fall height is limited by the length of the first part of rope.

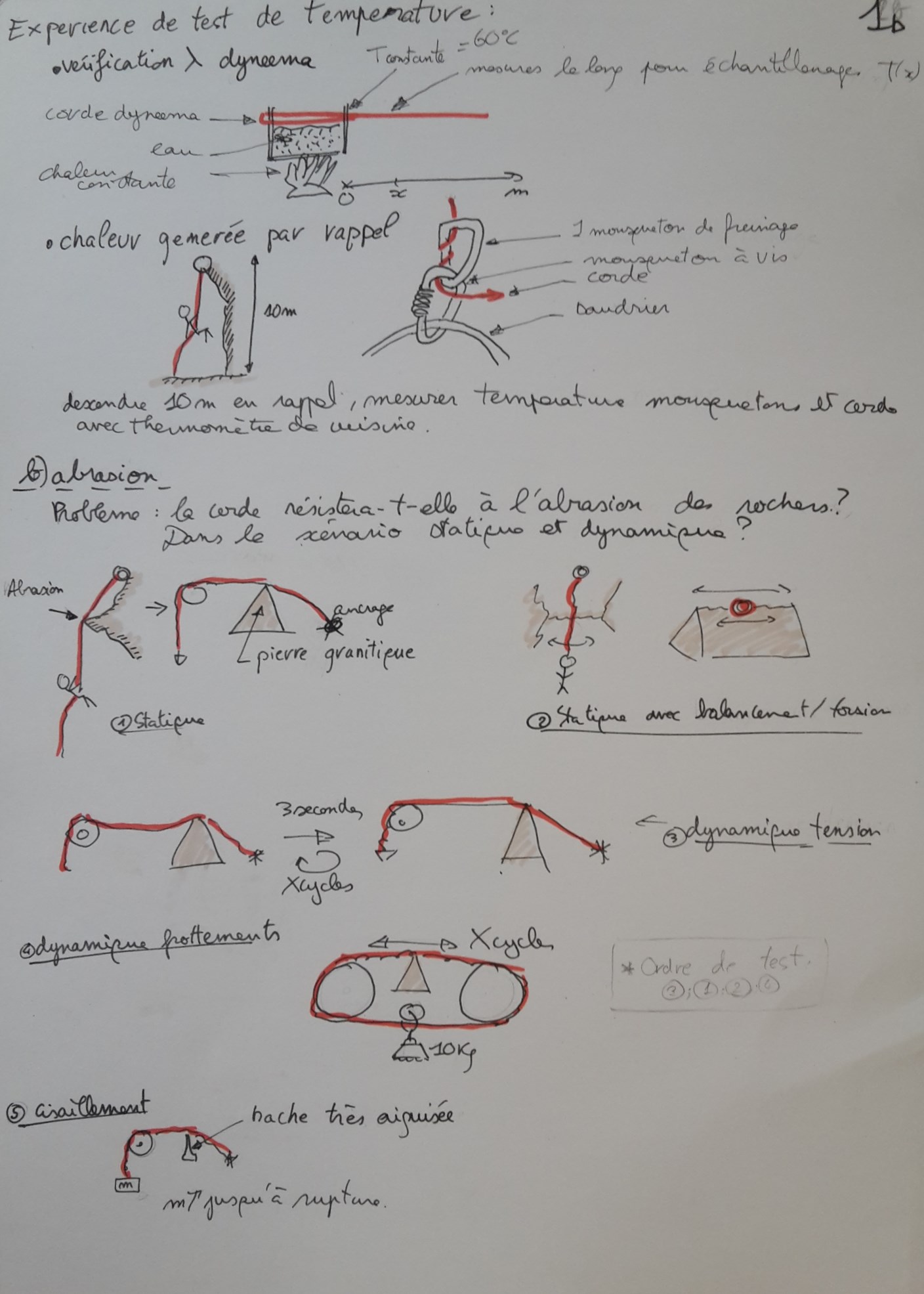

I performed some very crude experiments by testing a prototype on a climbing wall, and by testing a way to belay such a thin (in my case, 2.5mm) rope, using a carabiner as a brake

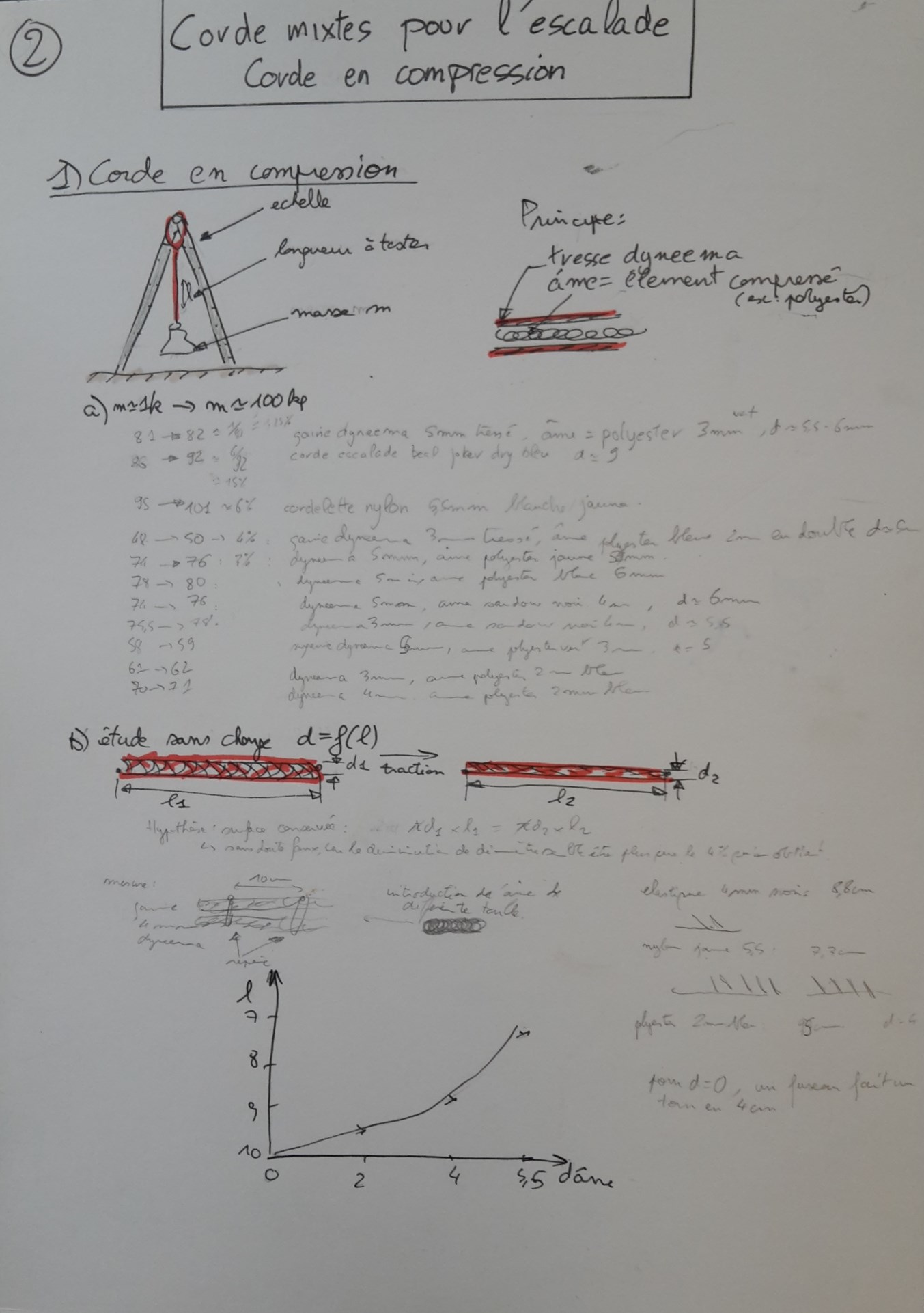

Compressive rope

The second approach is an attempt to transform super light, super sturdy, not stretchy rope into a stretchy one.

The idea is to change the way a climbing rope absorb shocks. The current climbing rope stretch, and by resisting this stretch they absorb energy.

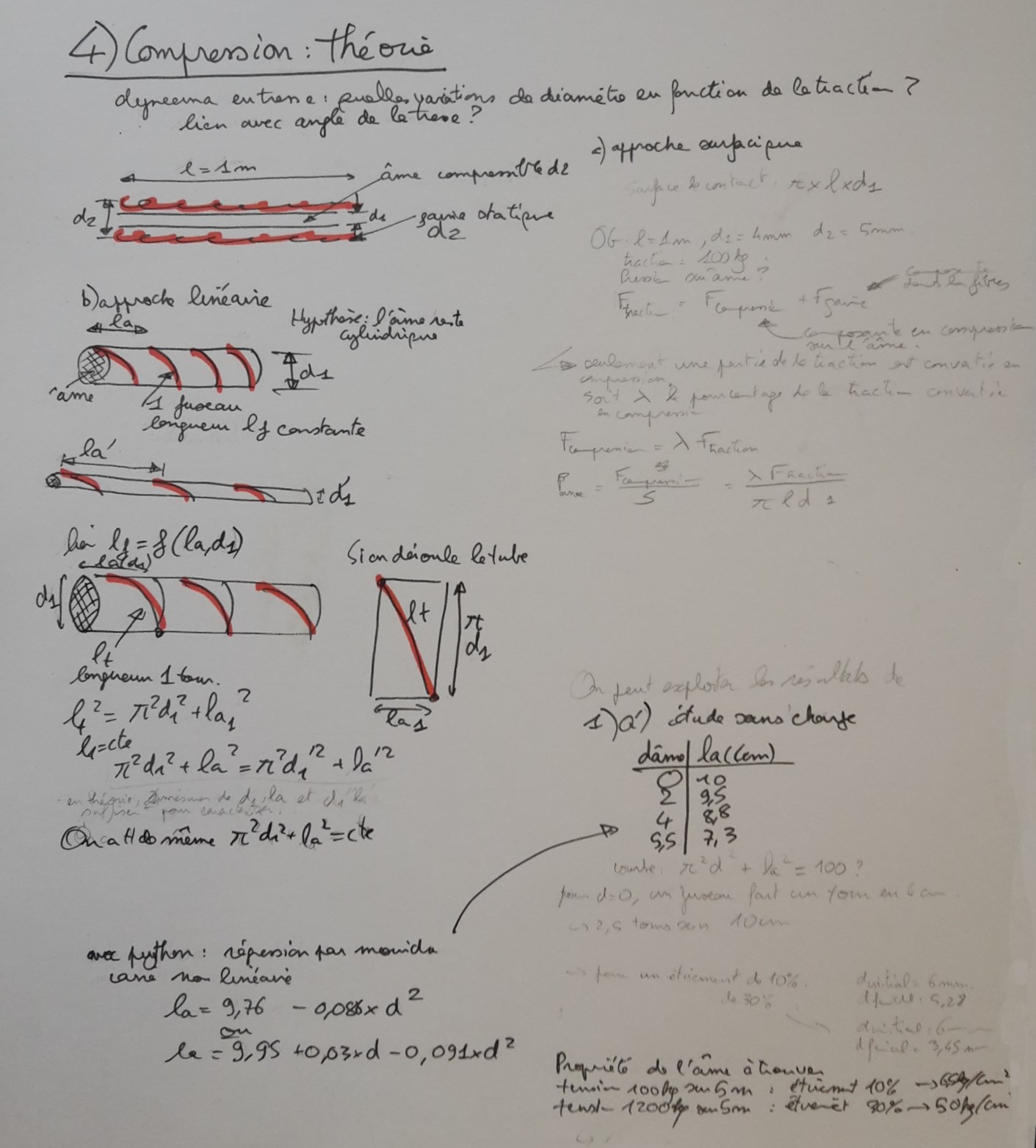

Yet the modern dyneema braids have a singular property that has been extensively used in current ropework: when the braid is put under tension, it tightens itself and slightly reduces its diameter. And the more you pull, the more the braid tighten.

So the idea is to put a soft material (for instance a polyester rope) inside the braid as a core. When the braid is under tension, it compresses the core. In return, the core deforms, and this deformation absorbs energy.

So instead of relying of stretching (elongation) of the rope, we rely on compression of the core ! The key is that there are much more material that are lightweight and resist compression rather that lightweight and resist elongation.

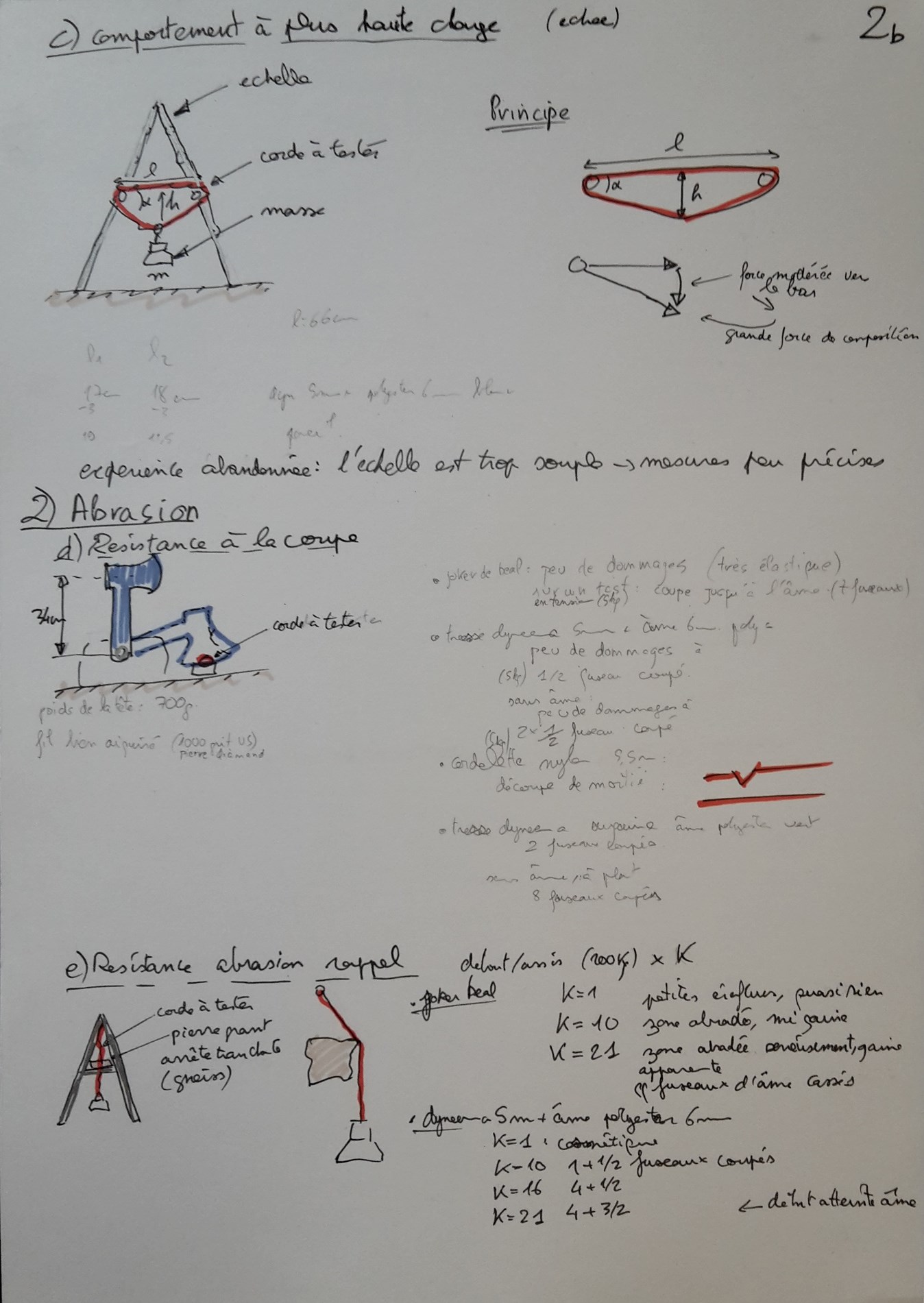

I performed some experiment to proof this idea, I could explore the behavior up to 100kg of tension, but couldn’t test it up to the 1200kg (12g for a 100kg person, the normative upper limit).

details

These concepts are summarized in the following illustration:

I made some experiments to test the resistance to abrasion and potential stretch of compressive rope. The goal was mainly a proof of concept, as I have no access to the actual test machines (applying several tones of pressure…)